Imagine you want to change your motor’s speed for a project in 2025. To pick the right vfd drive, match the drive’s details to your motor’s needs. Think about full load amperage, voltage, overload, application type, environment, and carrier frequency. Some people choosethe wrong size vfd or forget about temperature and humidity. Always look at the motor nameplate and use Canroon’s help. Make sure everything works together and think about future needs before picking a variable frequency drive.

Puntos clave

- Always look at the motor nameplate for full load amperage. This number helps you pick the right VFD size. The right size keeps your motor from getting too hot.

- Make sure your VFD voltage matches your motor and power supply. If the voltage does not match, your motor can get damaged over time.

- Know what kind of load you have. Constant torque loads need different VFD settings than variable torque loads. This can change how well your motor works.

- Think about things like temperature and altitude. Hot places or high places can make your VFD get too hot or stop working.

- UseCanroon’s online tools to help you pick the right VFD fast. Their support can make the job easier and more correct.

Dimensionamiento del variador de frecuencia

Choosing the right vfd drive starts with understanding your motor’s needs. You want your vfd to work safely and efficiently. This means you must look at the numbers on your motor and match them to the vfd drive you select. Let’s break down the most important steps.

Corriente a plena carga

You should always check the motor nameplate for the full load amperage. This number tells you how much current your motor draws when running at full power. The industry standard says you mustsize your vfd based on this full load amperage, not just the horsepower. Horsepower can be misleading because it does not always show the true current draw.

To size your vfd, find the full load amperage on the nameplate. Multiply this number by two if your application has heavy loads or frequent starts. Then, choose a vfd drive with a current rating at least as high as your calculated value. This method helps you avoid overheating and keeps your system running smoothly.

Consejo: Always use the motor rated current for sizing, especially if your load changes often. If your application has high torque or starts and stops a lot, you may need to pick a larger vfd.

Compatibilidad de voltaje

Matching voltage is just as important as matching current. You must make sure the voltage rating of your vfd matches both your motor and your worksite power supply. If you mismatch the voltage, you can causewinding stress, bearing failure, or even insulation breakdown in your motor. High-voltage peaks from the vfd can damage the motor over time, especially if the insulation is not strong enough.

Here is a quick look attypical voltage tolerances for vfd drives:

If the voltage drops too low, your motor may overheat or run poorly. If the voltage goes too high, you risk damaging the motor’s internal parts. Always check that your vfd, motor, and power supply are in the same voltage class.

Nota: For single-phase motors, you may need a special vfd or a derated drive. For three-phase motors, always match the phase and voltage exactly.

Potencia nominal

Horsepower is a common way to describe motors, but it should not be your only guide. You must always check the full load current first. Still, horsepower can help you compare different vfd options. For most fans and pumps (variable torque loads), you can pick a vfd with a horsepower rating equal to or just above your motor. For conveyors or mixers (constant torque loads), you may need a vfd with a higher horsepower rating to handle extra torque.

Follow these steps for sizing:

- Check the motor nameplate for full load amperage at the rated voltage and frequency.

- Make sure the vfd’s output current rating meets or exceeds this value.

- Match the vfd’s voltage class to your motor and power supply.

- Consider overload needs. Some applications need the vfd to handle 150% of rated current for short times.

- Think about your environment. High temperatures or dust may require a larger vfd or special enclosure.

If you feel unsure, Canroon offers online tools to help you size your vfd drive. These tools let you enter your motor details and get a list of matching vfd models. This makes the process faster and more accurate.

Consejo: Oversizing your vfd can help in tough applications, but it is not always needed. Use Canroon’s selection tools to find the best fit.

Aplicación del variador de frecuencia

Tipo de carga

You need to know yourload type before picking a vfd. The load type changes how the vfd works with your motor. There are two main load types. One is constant torque. The other is variable torque. Constant torque loads need the same torque at every speed. You find these in things like conveyors and elevators. Shredders and extruders also use constant torque. Variable torque loads need more torque as speed goes up. Fans, blowers, and pumps are examples of this.

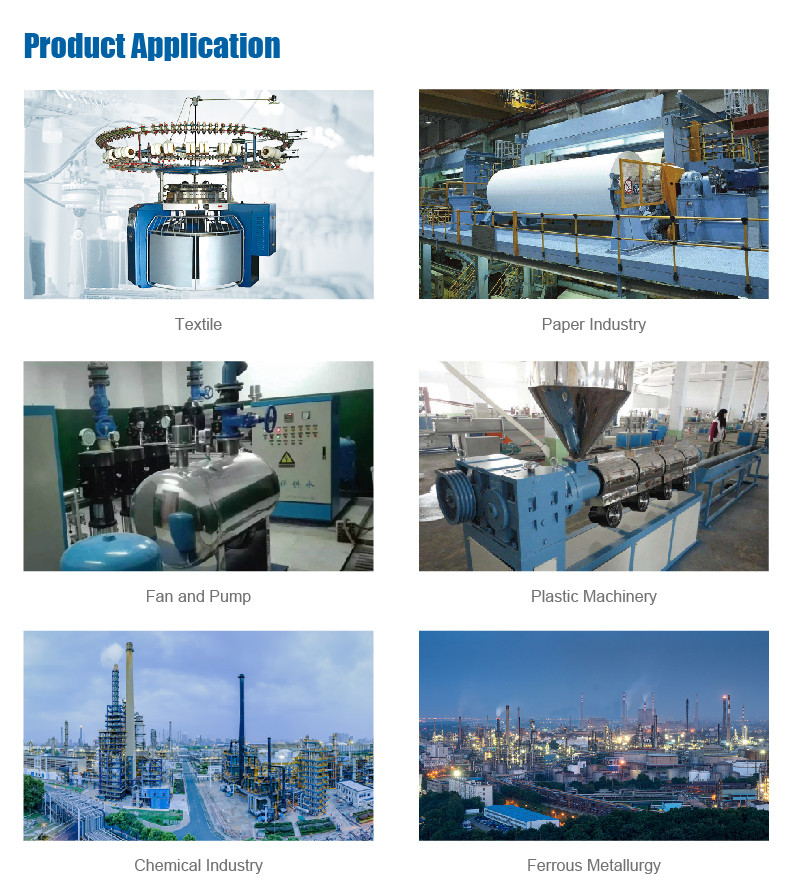

If you work in food and beverage, vfd drives help with mixing. In HVAC, you can save energy by changing motor speed. Material handling uses vfd to control conveyors and pumps. Mining and pumping systems use vfd for safety and better work.

Capacidad de sobrecarga

You must check theoverload capacity for your job. Some jobs need the vfd to handle extra current for short times. Heavy-duty jobs, like conveyors or crushers, need higher overload ratings. Lighter jobs use normal duty.

You should always match the vfd to your motor and job. This keeps your system safe and working well.

Frecuencia portadora

Carrier frequency settings change how your vfd runs the motor. A higher carrier frequency makes the motor quieter. But it can lower efficiency and make more heat. Lower carrier frequencies can make more noise. They help reduce electromagnetic interference.

You can use shielded cables and good grounding to control EMI. Canroon supports many jobs and can help you set the right carrier frequency for your vfd.

Factores ambientales del variador de frecuencia

Altitud

You need to think about altitude when you install avfd. High places, like mountains, have thinner air. This thin air cools your vfd less than air at sea level. When you go above 1,000 meters (about 3,300 feet), the cooling power drops. Your vfd may get hotter and not work as well. At very high altitudes, like above 4,000 meters, the air’s insulation ability also drops. This can lead to voltage problems. Manufacturers often suggest you lower the vfd’s power rating or add extra cooling if you install it high up. Sometimes, you may need to reduce the voltage to keep your motor and vfd safe.

- High altitude means less cooling for your vfd.

- Lower air pressure can cause your vfd to overheat.

- You may need to derate the vfd drive or add fans.

- The air’s insulation gets weaker, so voltage may need to be reduced.

Temperatura

Temperature changes can affect how well your vfd works. If the air around your vfd getstoo hot, the inside parts can overheat. This shortens the life of your vfd and your motor. You should always check the maximum temperature allowed for your vfd. If the room is too warm, you might need to add fans or air conditioning. High humidity can also cause problems. Moisture can lead to short circuits or block the cooling system. Always keep your vfd dry and cool.

Consejo: Watch your vfd’s temperature during operation. If it gets too hot, lower the load or improve cooling.

Consejos de instalación

Proper installation helps your vfd last longer and keeps your motor safe. Here are somebest practices:

- Place your vfd in a cool, dry spot with good airflow.

- Avoid dust, moisture, and corrosive gases.

- Make sure you can reach the vfd for checks and repairs.

- Use shielded cables and ground everything well to stop electrical noise.

- Enter your motor’s nameplate data into the vfd settings.

- Double-check all wiring and follow the manufacturer’s instructions.

Common mistakes include loose wires, wrong settings, or ignoring the manual. These errors can cause your vfd or motor to fail early. If you face tough conditions, like high altitude or heat, ask Canroon for advice. Their team can help you pick the right vfd and give tips for safe installation.

Consejos para seleccionar un variador de frecuencia

Lectura de la placa de identificación

You should read the motor nameplate before picking a vfd. The nameplate has the most important details for a safe match. Look for these things:voltage, phase number, frequency, power rating, shaft torque at different speeds, thermal overload ability, low-speed needs, and the lowest efficiency needed by rules. If something is missing or hard to read, compare what you have with your job’s needs. Check the flow rate, head, speed, and voltage. If you are not sure, ask the manufacturer for help. Doing this helps you avoid problems later.

Consejo: Always check the nameplate again before putting data into your vfd.

Errores comunes

Many people make the same mistakes when choosing a vfd. You can avoid problems if you know what to look for.

If you pick a vfd that is too small or too big, your motor may not work well. It could get too hot or even break. Sometimes, you need more cooling at low speeds or with heavy loads.

Herramientas de Canroon

Canroon gives you tools and support to help you pick a vfd. You get fast help when you have questions. Their drives work every day and last a long time. They have smart features to save energy and give smooth control. Setup is simple with your system. You can use Canroon’s online tools to enter your motor details and find the right vfd.Fast help lets you fix problems quickly. Many people say Canroon’s help is easy to use and reliable.

Nota: Good support and the right tools make your vfd project safer and better.

You can pick the right vfd drive by using easy steps. First, make sure the drive matches your motor’s needs. Check both the supply voltage and the motor voltage. If you use long cables, think about voltage drops. Look at the motor’s insulation, cooling, and bearings to see if it is inverter duty. Next,check the overload capacity and the IP protection rating. Built-in controllers help keep control steady. You can use Canroon’s tools or ask experts for help. Before buying, use this checklist:

- Make sure supply and motor voltage match.

- Watch out for voltage drops.

- Check motor insulation and cooling.

- Look at overload and protection features.

- See if the manufacturer gives good support.

Consejo: Always check every detail to keep your system safe and working well.

Preguntas frecuentes

What happens if you choose a VFD that is too small for your motor?

If you pick a VFD that is too small, your motor may overheat or shut down. The VFD can fail early. Always match the VFD size to your motor’s full load amperage.

Can you use one VFD for multiple motors?

You can use one VFD for several motors, but all motors must start and stop together. The total current must not exceed the VFD’s rating. You cannot control each motor’s speed separately.

How do you know if your motor is inverter duty?

Check the motor nameplate for “inverter duty” or ask the manufacturer. Inverter duty motors have better insulation and cooling. They work well with VFDs and last longer.

What maintenance does a VFD need?

- Clean the VFD’s air vents.

- Check for dust and moisture.

- Inspect wiring and connections.

- Watch for warning lights or error codes.

Regular checks help your VFD last longer and work safely.

Anterior:

Siguiente:

Suscríbete para actualizaciones