Tienes muchas opciones al elegir una máquina de temple por inducción para el precalentamiento de acero. Debes adaptar las características de la máquina al tipo de acero, tamaño y necesidades de precalentamiento. Esto te ayuda a obtener mejor eficiencia y calidad. Si eliges un fabricante líder, obtendrás funciones avanzadas. Estas características ayudan a que la máquina funcione mejor y consuma menos energía. Considera estos puntos clave:

El control preciso y la reproducibilidad aceleran la producción.

La integración sencilla ahorra costos y evita problemas.

El tratamiento térmico confiable evita interrupciones en el trabajo. Analiza los detalles técnicos y tus necesidades prácticas. También verifica la reputación del fabricante.

Conclusiones clave

Eligecaracterísticas de máquina que se ajusten a tu tipo y tamaño de acero. Esto mejora resultados y ahorra energía.

Adquiere una máquina con buen control de calentamiento/enfriamiento. Esto fortalece las piezas de acero.

Asegúrate que la potencia y frecuencia coincidan con tus necesidades. Esto acelera el calentamiento y reduce el consumo energético.

Evalúa la reputación del fabricante y su soporte técnico. Garantiza buen funcionamiento y asistencia cuando la necesites.

Considera el espacio de trabajo y cómo se integrará la máquina. Optimiza la productividad y minimiza inconvenientes.

Evaluación de necesidades para máquina de temple por inducción para precalentamiento de acero

Elegir lamáquina de temple por inducción correcta para precalentamiento de acero requiere entender tus necesidades. Debes considerar: tipo de acero, tamaño de piezas, profundidad de calentamiento y temperatura requerida. Estos factores aseguran un equipo eficiente y energéticamente óptimo.

Tipo de material y tamaño de pieza

Identifica el acero a utilizar.Aceros al carbono medio con baja aleación son comunes en temple por inducción. Son resistentes y duraderos, ideales para automoción y maquinaria. El contenido de carbono afecta la dureza superficial. Mayor carbono produce piezas más resistentes a fuerzas externas. Al seleccionar una máquina, considera también el tamaño de tus piezas. Piezas grandes/gruesas requieren mayor potencia y equipos adaptados. Una máquina adecuada a tu acero y dimensiones optimiza resultados.

Consejo: Siempre verifica el nivel de carbono del acero y el tamaño de pieza antes de elegir equipo. Previene problemas futuros.

Profundidad de calentamiento y requisitos de temperatura

Define la profundidad de calentamiento requerida. La profundidad y distribución de tensiones afectan la calidad de la pieza. Para capas endurecidas profundas, necesitas máquinas potentes con frecuencia adecuada. La temperatura de precalentamiento también guía tu selección. Algunas máquinas con cables refrigerados por aire alcanzan 400°F. Sistemas refrigerados por líquido llegan hasta 1,450°F. La tabla muestra diferencias:

La máquina correcta para precalentamiento de acero alcanza temperaturas deseadas rápidamente con menor consumo energético, facilitando tu trabajo y manteniendo estabilidad.

Necesidades de temple y consistencia

Tras calentar el acero, frecuentemente requiere enfriamiento rápido (temple). El control de tasas de calentamiento/enfriamiento determina dureza y resistencia. El calentamiento por inducción permite control térmico rápido y preciso. El enfriamiento debe ser a velocidad adecuada: demasiado lento reduce dureza; demasiado rápido puede agrietar el material. La tabla resume aspectos clave:

Al seleccionar tu máquina, evalúa su capacidad para controlar calentamiento/enfriamiento. Un buen control garantiza resultados consistentes, mayor productividad y reducción de desperdicios.

Nota: Mantener procesos de calentamiento/temple estables mejora calidad de productos y vida útil del equipo.

Analizar detalladamente tus necesidades asegura que la máquina de temple por inducción para precalentamiento se adapte a tus operaciones, optimizando energía, eficiencia y resultados.

Factores clave en calentamiento por inducción

Selección de potencia y frecuencia

La elección correcta de potencia y frecuencia es crucial para un precalentamiento efectivo. Antiguos equipos de inducción usaban generadores de arco o motores-generadores con limitaciones de frecuencia. Los osciladores de tubo mejoraron el rendimiento pero tenían problemas de tamaño. Los modernosfuentes de alimentación de estado sólido revolucionaron el sector, permitiendo frecuencias superiores a 5 MHz para un precalentamiento más rápido y confiable.

Esta tabla muestra rangos de frecuencia óptimos para diferentes aplicaciones:

La selección adecuada de potencia y frecuencia optimiza el calentamiento por inducción, reduciendo consumo energético y mejorando resultados.

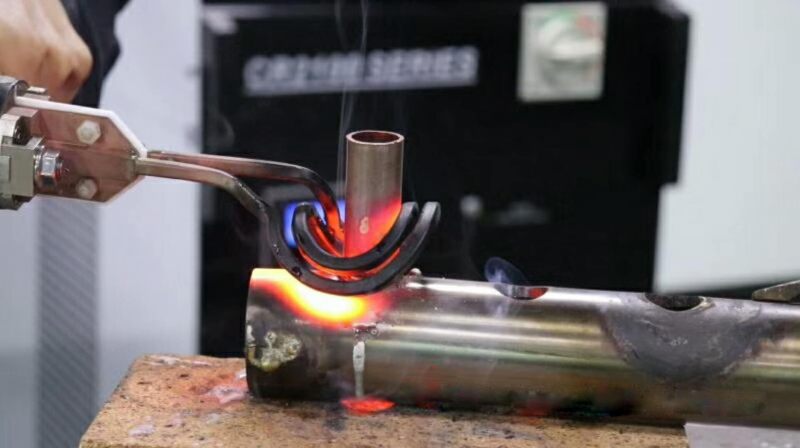

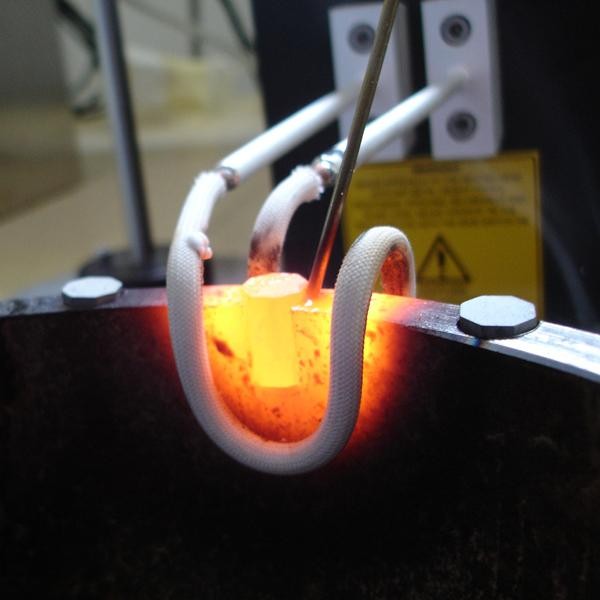

Diseño de bobinas y acoplamiento

El diseño de bobinas es fundamental en calentamiento por inducción. Debes adaptar la bobina a tu aplicación y material. Un buen diseño garantiza los resultados esperados. Realiza pruebas para verificar seguridad y robustez. El flujo de agua de refrigeración es crítico: flujo insuficiente afecta la transferencia térmica. Los concentradores de flujo magnético dirigen el calor eficientemente. Adaptar la impedancia de la bobina a la fuente de alimentación maximiza el rendimiento.

Diseña bobinas específicas para cada aplicación.

Prueba bobinas para seguridad y resistencia.

Garantiza flujo adecuado de agua de refrigeración.

Incorpora concentradores de flujo magnético.

Ajusta impedancia de bobina a la fuente de alimentación.

El acoplamiento entre bobina y pieza también es vital. Se requiere un acoplamiento electromagnético fuerte para un calentamiento uniforme. La densidad de corriente en el acero debe ser homogénea. Mantén una separación de 0.5-3mm entre bobina y pieza. La forma de la bobina influye en el flujo de corriente y patrón de calentamiento.

Consistencia del patrón de calentamiento

Busca patrones de calentamiento consistentes durante el proceso. Esto garantiza dureza uniforme y evita defectos. La tabla muestra métodos para mantener uniformidad:

Mantener patrones de calentamiento estables evita irregularidades en dureza y deformaciones. Puedes ajustar la dureza modificando parámetros de precalentamiento. Esta precisión es crucial para piezas sometidas a altos esfuerzos. Una velocidad constante de la pieza mejora calidad y rendimiento.

Calidad y confiabilidad del producto

Estándares de calidad de máquinas

Quieres que tumáquina de temple por inducción funcione consistentemente. Los equipos de calidad parten de estándares rigurosos. Máquinas que cumplen normas como ISO 9001, CE y RoHS son más seguras y eficientes. Estas certificaciones garantizan seguridad y capacidad para trabajos exigentes, además de contribuir a la resistencia de tus piezas de acero.

Los fabricantes verifican la calidad mediante múltiples pruebas en fábrica, mediciones de rendimiento y, en ocasiones, validaciones por terceros. Puedes confiar en equipos que superan estos controles. Máquinas confiables reducen averías y ayudan a cumplir tus objetivos.

Equipos que pasan controles de calidad brindan tranquilidad y te ayudan a alcanzar tus metas.

Confiabilidad y experiencia del fabricante

Elige un fabricante con amplia experiencia. Fabricantes calificados saben configurar frecuencia de calentamiento y tiempo de temple óptimos, previniendo grietas o deformaciones en el acero. Conocen cómo los ajustes afectan el calor y tensiones en el material, prolongando su vida útil y rendimiento.

Los buenos fabricantes ofrecen más que máquinas: brindan capacitación, soporte y asesoría. Sus equipos ayudan en instalación y resolución rápida de problemas. Obtienes mejores resultados trabajando con expertos comprometidos con la seguridad.

Fabricantes expertos seleccionan la mejor frecuencia de calentamiento y tiempo de temple para evitar deformaciones.

Conocen cómo los ajustes afectan calor y tensiones, prolongando la vida del acero.

Su experiencia y enfoque en seguridad optimizan el funcionamiento y durabilidad de los equipos.

Buenos fabricantes te ayudan a evitar errores costosos y mantener la continuidad operativa.

¿Por qué elegir Canroon?

Canroon es líder en fabricación de máquinas de temple por inducción. Su modelo CR2000 cumple estrictas normas como CE e ISO9001. Cada equipo ofrece alta calidad y rendimiento consistente. Las máquinas Canroon destacan por: ahorro energético, controles precisos y construcción robusta, ideales para fábricas y obras.

Puedes elegir entre modelos como la Máquina de Precalentamiento por Inducción Móvil 120kva. Estos equipos calientan tuberías rápidamente y se adaptan a múltiples aplicaciones. Canroon diseña máquinas intuitivas y duraderas.

Ahorro energético

Controles digitales

Sistema de refrigeración por aire robusto

Control preciso de temperatura

Protección IP54

Canroon proporciona excelente soporte postventa: asistencia en instalación, capacitación y consultas técnicas. Su equipo garantiza funcionamiento óptimo a largo plazo. Al elegir Canroon, obtienes calidad y confiabilidad duraderas.

El compromiso de Canroon con la calidad y confiabilidad te ayuda a obtener mejores resultados y reducir costos.

Consideraciones prácticas para integración de máquinas de temple por inducción

Espacio de trabajo e instalación

Planifica tu área de trabajo antes de instalar el equipo. La configuración de tu maquinaria afecta su integración en el taller. Sistemas de inducción verticales/horizontales se adaptan a diferentes formas y tamaños de piezas. Los sistemas horizontales son ideales para piezas largas y producción rápida. Los verticales manejan múltiples ejes simultáneamente, pero requieren cuidado en el manejo de piezas. Esta tabla muestra impactos de la configuración:

Consulta con el fabricante para seleccionar la mejor configuración según tu espacio. Una buena planificación previene problemas y optimiza el trabajo.

Integración y flexibilidad del sistema

Al integrar una máquina a tu línea, busca compatibilidad óptima. Los sistemas de inducción manejan lotes pequeños o grandes. Puedes ajustar parámetros rápidamente para diferentes materiales (hierro fundido, aleaciones especiales). Los cambios rápidos minimizan tiempos muertos. Ventajas de configuraciones flexibles:

Cambio sencillo entre metales/aleaciones.

Control preciso de temperatura y dureza.

Ahorro de tiempo con ajustes rápidos y mínimas interrupciones.

Configuraciones escalables que crecen con tu negocio.

Fabricantes con trayectoria probada pueden ayudarte a implementar máquinas en diversos entornos. Esta flexibilidad mejora eficiencia operativa y reduce consumo energético.

Soporte postventa

Busca un sólido soporte postventa. Un buen soporte incluye: asistencia en instalación, capacitación y respuesta a consultas. Tu fabricante debe ofrecer servicio rápido y expertise técnico. Un soporte robusto mantiene tu máquina operativa y resuelve problemas eficientemente, prolongando su vida útil y mejorando resultados.

Consejo: Consulta sobre soporte postventa antes de comprar. Un buen soporte facilita tu trabajo y protege tu inversión.

Al seleccionar una máquina de temple por inducción para precalentamiento de acero, considera factores clave: resistividad del metal, profundidad de calentamiento, frecuencia operativa, potencia utilizada y diseño de bobinas. Adaptar las características del equipo a tus necesidades permite controlar tasas de enfriamiento y manejar tensiones de soldadura eficientemente, produciendo piezas más resistentes y optimizando tu productividad. Para asesoría o equipos de calidad, consulta con empresas confiables como Canroon.

Preguntas frecuentes

¿Qué es el temple por inducción?

El temple por inducción endurece rápidamente la superficie del acero mediante campos electromagnéticos, mejorando su resistencia y durabilidad. Ideal para partes sometidas a alto desgaste.

¿Cómo elijo la frecuencia correcta para mi máquina?

Selecciona la frecuencia según el tamaño de tu pieza y profundidad de endurecimiento requerida. Frecuencias altas calientan superficialmente; frecuencias bajas penetran más. Consulta a tu proveedor para recomendaciones específicas.

¿Puedo usar temple por inducción en todos los aceros?

Muchos aceros son aptos, especialmente medios/altos en carbono. Aceros bajos en carbono pueden no alcanzar la dureza deseada. Siempre verifica la composición del material.

¿Qué mantenimiento requiere una máquina de temple por inducción?

Limpia regularmente bobinas y revisa el sistema de refrigeración. Inspecciona componentes eléctricos para garantizar seguridad. Sigue siempre el manual del fabricante para un mantenimiento óptimo.

¿Por qué elegir una máquina certificada?

Las máquinas certificadas cumplen normas internacionales de seguridad y calidad, reduciendo riesgos operativos. Equipos con certificaciones ISO o CE ofrecen mayor confiabilidad y tranquilidad.

Suscríbete para actualizaciones